Introduction to Powder Coat Oven Control Box

The Powder Coat Oven Control Box serves as the nerve center of any powder coating operation. It is a sophisticated assembly composed of a user - friendly control panel, reliable circuit breakers for safety protection, high - performance relays for electrical switching, and precision - engineered temperature controllers. These elements collaborate seamlessly to precisely manage the oven's temperature, power distribution, and overall operational sequence, playing a pivotal role in achieving flawless powder coating results.

Application Scenarios

This essential equipment finds its utility across a diverse range of industries. In the automotive sector, it is indispensable for applying durable and aesthetically pleasing powder coatings to car bodies, wheels, and interior components. The furniture industry also heavily relies on it to enhance the finish and longevity of wooden and metal furniture pieces. Additionally, in metal fabrication, it ensures that fabricated parts are coated with a protective and attractive powder finish, suitable for various applications from industrial machinery to household appliances.

Price Range

The cost of

Powder Coat Oven Control Box s can span a wide spectrum. Entry - level models, designed for small - scale or hobby - based operations, can be found at prices starting from around a few hundred dollars. On the other hand, for large - scale industrial applications that demand high - capacity and advanced control features, the price can escalate to several thousand dollars, reflecting the complexity and performance capabilities of these units.

Correct Usage

Proper usage begins with a meticulous installation process, strictly following the manufacturer's detailed instructions. Before initiating the powder coating process, carefully input the desired temperature and time settings on the control panel. During the operation, it is crucial to continuously monitor the oven's performance through the control box, checking for any irregularities in temperature or operation status.

How to Choose

When selecting a

Powder Coat Oven Control Box , several factors need to be taken into account. First, assess your production requirements, including the volume of items to be coated and the size of the oven. A higher production volume may necessitate a more powerful and feature - rich control box. Next, consider the required temperature accuracy, especially if you are working with sensitive powder coatings. Finally, research the brand's reputation in the market and the quality of after - sales service, as these can significantly impact the long - term performance and usability of the control box.

Safety Precautions

Safety should always be a top priority when dealing with powder coat oven control boxes. Keep the control box in a dry and dust - free environment to prevent potential damage to the internal components. Ensure that the unit is properly grounded to safeguard against electric shock hazards. Under no circumstances should the control box be opened while it is in operation, as this can expose you to live electrical parts.

Rationality Analysis

A thoughtfully designed

Powder Coat Oven Control Box offers numerous advantages. It streamlines the powder coating process, increasing productivity by reducing the time required for temperature adjustments and overall operation. Moreover, it helps in optimizing energy consumption, resulting in cost savings over time. By maintaining consistent temperature and control, it guarantees a uniform and high - quality powder coating finish, reducing the likelihood of defects and rework.

Q&A

Q: What should I do if the oven temperature fluctuates significantly?

A: Start by inspecting the temperature controller within the powder coat oven control box. It may require recalibration to regain accurate temperature control. If the issue persists, the controller might need to be replaced.

Q: Is it feasible to use a small - scale oven control box for large - scale production?

A: Unfortunately, no. Small - scale control boxes lack the power handling capacity and advanced control features necessary to manage large - scale operations effectively, leading to inconsistent results and potential equipment failures.

Q: How frequently should I conduct maintenance on the control box?

A: To ensure its optimal performance, it is advisable to perform regular maintenance every 3 - 6 months. This includes checking for loose connections, cleaning internal components, and testing the functionality of critical parts.

Q: Do different types of powder coatings demand distinct control boxes?

A: Absolutely. Some powder coatings have specific curing requirements, such as narrow temperature ranges. Control boxes designed for these coatings are optimized to provide precise temperature control within those specified ranges.

Q: Can I install the powder coat oven control box on my own?

A: While it may seem tempting to do a DIY installation, it is highly recommended to have a professional handle it. Professionals have the expertise to ensure correct wiring, proper grounding, and overall safe installation, minimizing the risk of electrical accidents.

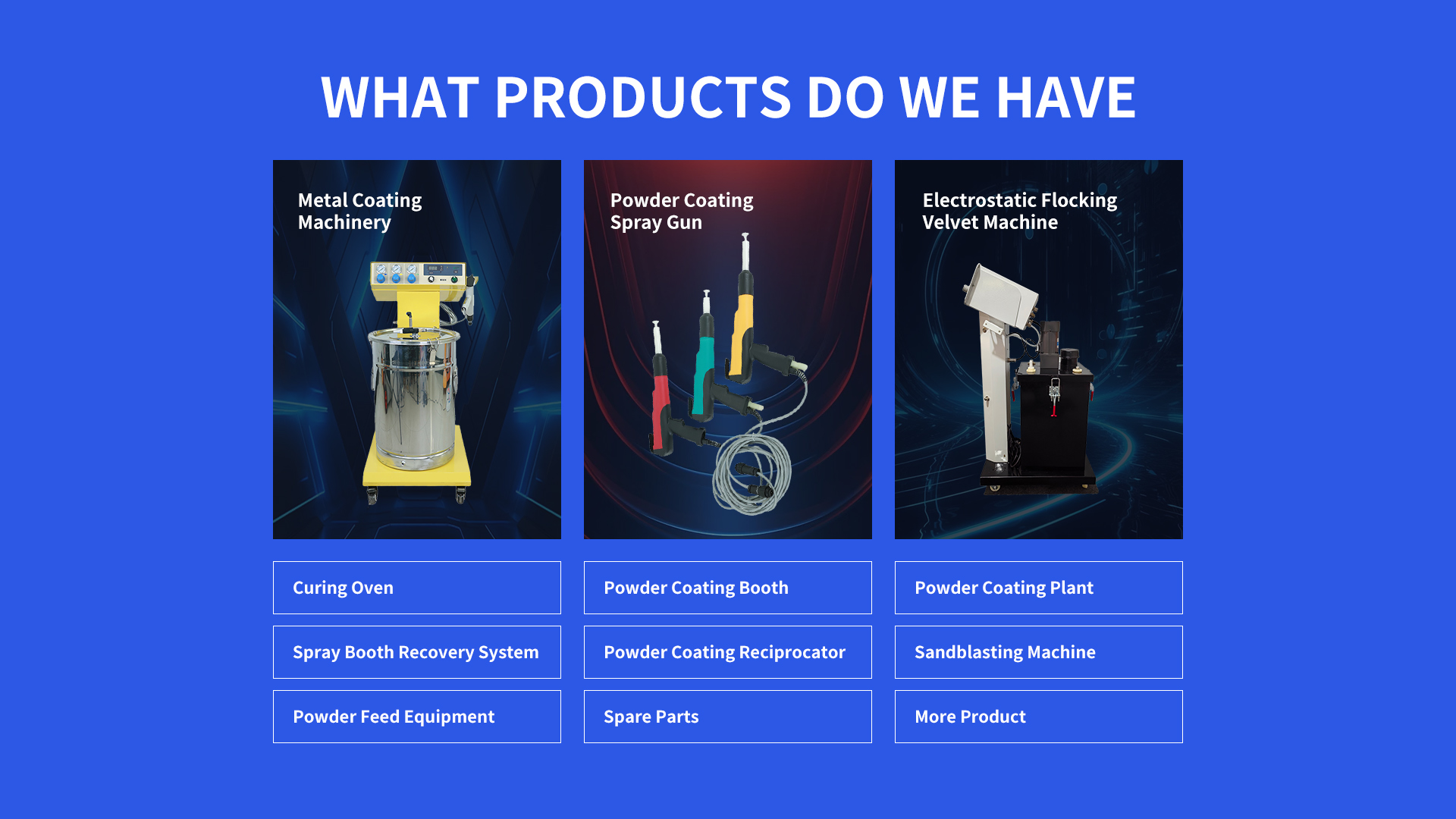

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com